CONTINUOUS AIR QUALITY MONITORING

MONITOR AIR QUALITY WITH EASE

What it does ? And why?

What it does ? And why?

CAAQMS application

features

Device Connectivity Configuration

Real Time Monitoring

1. Current sensor status (online/offline).

2. Last data report time and last reported value.

Sensor Trend

Data

Sensor data can provides following:

Last one hour data.

Last six hours data.

Last seven days data

Last twenty eight days data.

Sensor Calibration

Sensor Calibration

IOT middleware device performs internal logical calculations to get sensor values.

It takes Factory offset and Zero offset also into consideration.

At time of sensor configuration both Factory offset and Zero offset values are set.

To calculate factory offset—

By default, sensors provide raw data in form of current and voltage from gas sensors. But

our

device can convert the raw data into calibrated data based on two offsets—

Sensor reading also varies based on the temperature and humidity, that’s why our device provides correction based the following compensation data—

And while providing the factory offset you don’t need to provide or calculate the factor. All you need to do is provide the raw reading from the sensor and expected reading and the factor will auto-calculated.

All the background data with time stamp will be stored and can be downloaded.

Device Maintenance

Device Maintenance

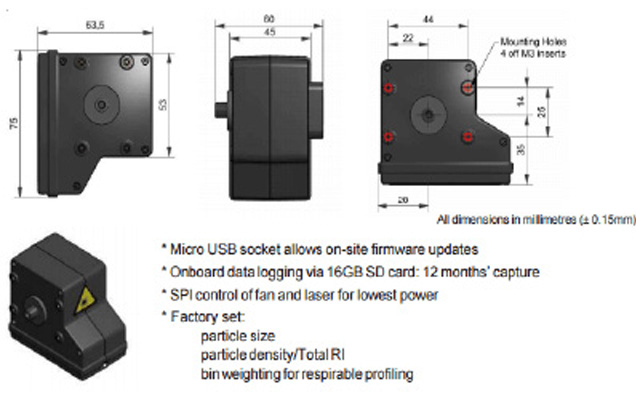

The Optical Particle Monitor unit is used for particulate matter monitoring 2.5/10 PPM. It can also provide PPM 1.0. The sensor module used in this CAAQMS design measures particles from 0.38 micron to 17 micron diameter accurately, repeatedly, and with minimal maintenance using the patented ‘pump-less’ design. It will still have a small inbuilt fan. It can be noted that unlike other OPC, it does not use a Pump along with a filter that gets very dirty in a typical high pollution environment. It uses a different approach. The patented OPC-N2 uses an elliptical mirror and dual-element photo-detector to create a ‘virtual sensing zone’ in free space at the centre of an open scattering chamber. The OPC-N2 classifies each particle size, at rates up to ~10,000 particle per second, recording the particle size to one of 16 “bins” covering the size range from 0.38 to 17 μm. The resulting particle size histograms can be evaluated over user-defined sampling times from 1 to 10 second duration. This histogram data and air temperature are transmitted via an SPI interface to a host computer.